Read Our Blog

TIG vs MIG Welding: Know the Complete Difference

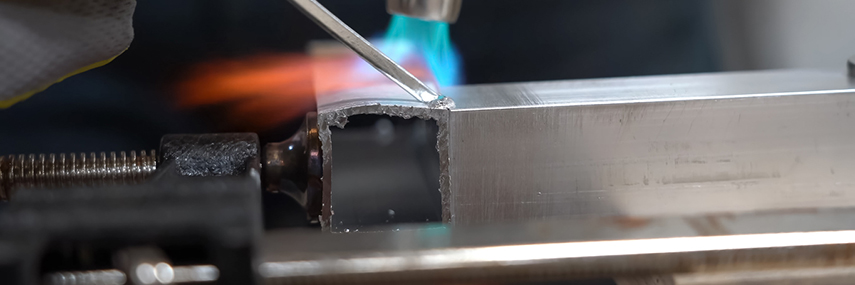

TIG welding and MIG welding are the most popular techniques known for their production efficiency and high quality. They have unique processes, benefits, and disadvantages and deliver different results, which is why they are applicable in distinct scenarios. It helps to understand MIG vs TIG welding technique comparison to choose the right one for your needs. Read on to learn the essentials and make an educated decision.

7 Major Differences Between TIG & MIG Welding

| Point of Difference | TIG Welding | MIG Welding |

|---|---|---|

| Power Source | The power source for this welding technique is usually AC for aluminum and DC for steels. | MIG welders typically use the DC power source. |

| Metal Selection | TIG welding is more suitable for thin metals because it offers better operational control, reducing the chances of destroying the workpiece. | MIG welding is more suitable for working with thick metals. |

| Electrode | TIG welders use non-consumable electrodes such as tungsten. They create electric arcs as they do not melt during the process. | MIG welding uses consumable electrodes that act as fillers and create electric arcs, typically made from steel, nickel alloy, aluminum alloy. |

| Shielding Gases | Although argon is the shielding gas in TIG welding, a mixture of helium and argon is sometimes used, depending on the requirements. | Argon/CO2 mixed gas is the most common shielding gas in MIG welding. Other gases include Argon/oxygen, CO2 /helium/argon, and 100% CO2 |

| Welding Torch | Although water and air-cooled torches are effective, TIG welding typically uses water-cooled ones as they generate more heat and are suitable for heavy-duty work. | MIG welders use both air-cooled and water-cooled torches. The former is lighter and cheaper. |

| Speed & Quality | Most sheet metal fabricators prefer TIG welding as it delivers a clean finish. However, it is slower than MIG welding. | MIG technique also produces quality welds and is much faster than TIG welding. |

| Cost | This is the more expensive method due to the cost of components used, the time required, and higher detailing. | MIG welding is less expensive than the TIG technique. |

MIG vs TIG Welding: Which is the Best?

Gas Tungsten Arc Welding or TIG is an arc welding process typically suitable for metals having about 100mm thickness. It uses a non-consumable electrode to create an electric arc and generate the heat required to melt the filler material and join the metal. It is enclosed by an inert gas, mainly argon, which shields it from atmospheric elements. TIG welding creates better welds but is a slower process.

Advantages of TIG Welding

- It is accurate and delivers quality results when it comes to aesthetics.

- This method offers better operational control than MIG.

- TIG welding is eco-friendly.

- It requires low maintenance as it uses non-consumable electrodes.

Disadvantages of TIG Welding

- TIG welding is expensive due to more filler materials and the slow process.

- It needs more prep time because it needs a clean surface.

- It takes a long time to produce the desired welds and requires an experienced operator.

Metal Inert Gas or MIG welding is an arc welding technique suitable for thin, thick materials such as steel and aluminum. The electric arc is formed at the end of a consumable electrode, and a shielding gas, usually carbon dioxide/Argon mixture, protects the weld pool. This process can be semi-automatic, or fully automatic.

Benefits of MIG Welding

- The welding process is less expensive and produces the desired result quickly.

- It is automatic and accurate.

- The equipment used in this technique is easily accessible.

Disadvantages of MIG Aluminum Welding

- It is not as environmentally friendly as the TIG method.

- It may lead to the formation of rust over time.

- MIG welding offers less operational control.

Although both welding techniques have their merits and demerits, here are some considerations to help you determine the best method for your needs:

Diversity

MIG welding is more diverse than the TIG process based on material compatibility. In addition, the consumable electrodes used help produce the electric arc and act as a filler, making it suitable for joining two different metals.

Speed

MIG welding is quicker than TIG welding because the machine is primarily automatic or semi-automated. It runs continuously, making the process more productive and efficient.

Difficulty Level

MIG welders do not need much technical expertise compared to the TIG welding method, which requires professional skills and knowledge.

Choose Nexal Aluminum for High-Quality Aluminum Welding

Nexal Aluminum offers the best aluminum welding consumables for both TIG and MIG welding, and excellent customer service. We encourage innovation to enhance operations and deliver top-grade products.

For more information about our range of consumables for welding aluminum, please complete our online form or call us at 1-905-629-8282. We will happily answer your questions and ensure you receive the products that fit your needs.